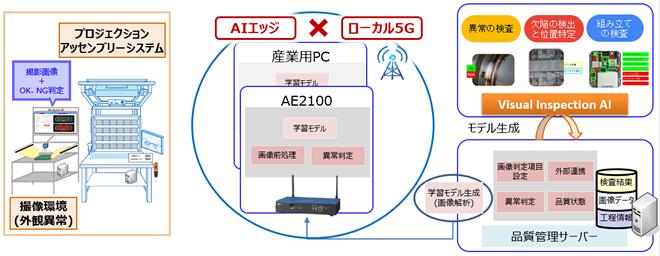

Edge terminals autonomously inspect product appearance abnormalities, and can be introduced and operated without AI knowledge

OKIOKI is a dedicated solution for high-speed and high-precision quality control of Google Cloud ™, "Visual Inspection AI" ("Visual Inspection AI", which is a "appearance abnormality judgment system" that saves labor and automates the inspection process at the manufacturing site with video AI. By combining Note 1), an automatic generation function of the learning model by AI and an autonomous inspection function by the generated model (hereinafter referred to as the automatic judgment model creation function) have been added. The "appearance abnormality judgment system" judges the appearance abnormality of the product in real time by analyzing the high-definition video of the parts and products to be inspected taken by the camera with the AI edge computer "AE2100" (Note 2). .. By adding the automatic judgment model creation function, it will be possible to introduce and operate this system easily and in a short period of time even at manufacturing sites that do not have AI expertise. This function will be provided from March 2022. This is the first case of co-creation with Google Cloud Japan GK, an OKI AI edge partner (Note 3).Appearance abnormality judgment using Google AI

The "Appearance Abnormality Judgment System" released by OKI in June 2021 (https://www.oki.com/jp/press/2021/06/z21018.html) is used for video data of parts and products to be inspected. On the other hand, it automates the visual inspection of the appearance by performing AI analysis worthy of the "eyes" and "knowledge (knowledge)" of experts. In the demonstration experiment conducted at OKI Honjo Factory (Honjo City, Saitama Prefecture), the assembly process The effect is that the work mistakes in Oki are reduced to "0" and the work time of the entire manufacturing process is reduced by 15%. However, in order to deal with the degree of fluctuating defects such as scratches and dents, it is necessary to regularly perform work to improve the accuracy of the generated learning model, such as combination of various parameters and model tuning by a professional AI engineer. had. In order to solve this problem, OKI has added an automatic judgment model creation function that utilizes machine learning using Google Cloud's "Visual Inspection AI" and "AutoML" (Note 4) in addition to the conventional image analysis engine. Added. By automating the learning model design, it is possible to generate a learning model even if the operator does not have AI expertise. Since the generated learning model is implemented in the edge terminal "AE2100", it is possible to autonomously perform visual inspection at the manufacturing site and immediately notify the operator of the result. Furthermore, if an unknown abnormality is detected during operation, the operator simply imports the image into the user screen, marks the defective part of each image, and labels it, and the learning model is automatically created. Since it can be generated, it always achieves high discrimination accuracy even in the field where there is no AI engineer. OKI plans to introduce this system to a new factory in the Honjo area, which will start operation as a smart factory in May 2022. By continuing to introduce each solution of "Manufacturing DX" (Note 5) including this system to our own factory and providing customers with various AI edge solutions that utilize the know-how, we will strengthen the on-site capabilities of the manufacturing industry and IT. And will contribute to the reform of OT (Note 6).Overview of appearance abnormality judgment systemSchematic diagram of appearance abnormality judgment system

By analyzing the high-definition images of the parts and products to be inspected taken by the camera with OKI's AI edge computer "AE2100", the appearance abnormality of the product is judged in real time, and the result is immediately notified to the operator. Trail data such as inspection images including judgment results and product information can be stored in the management server located at the upper level and used for quality control and analysis. Glossary Note 1: Please refer to the official website for details on Visual Inspection AI. https://cloud.google.com/solutions/visual-inspection-ai Note 2: AI with excellent environment resistance that accommodates AE2100 network cameras and various sensors and performs high-speed deep learning inference processing at the edge (field). Edge computer. Realizes reliability, real-time performance, and privacy protection by AI processing at the edge without sending a large amount of video data to the cloud. https://www.oki.com/jp/AIedge/ Note 3: AI Edge Partner An ecosystem for expanding the market in the AI edge area, capturing business opportunities, and creating various solutions using AI edge computers. Partner companies that support and participate in the "AI Edge Partnership". Note 4: Please refer to the official website for AutoML details. https://cloud.google.com/automl Note 5: Manufacturing DX (Manufacturing Digital Transformation) "Site transformation" that visualizes the manufacturing site, "IT / that links the site and management in a highly and bidirectional manner" OKI's solution concept aimed at realizing a smart factory, consisting of three transformations: "operational transformation" and "management transformation" that supports various management decisions such as environmental changes, legal compliance, and low-volume value-added production. Note 6: OT (Operational Technology) Technology for controlling and operating the hardware such as machine tools and factory equipment at the manufacturing site.Release-related link "Appearance abnormality judgment system" introduction site https://www.oki.com/jp/esc/pas/judgment.html Google's "Visual Inspection AI" introduction site (move to Google Cloud site) https: / /cloud.google.com/solutions/visual-inspection-ai "Manufacturing DX" introduction site https://www.oki.com/jp/esc/manufacturing/ A factory that considers disaster response and environmental load reduction in Honjo, Saitama Prefecture Newly established in the city https://www.oki.com/jp/press/2021/02/z20117.html Inquiries from the media regarding this matter Public Relations Department Phone: 03-3501-3835E-mail: press@oki.com Inquiry Form https://www.oki.com/cgi-bin/inquiryForm.cgi?p=015j Inquiries from customers regarding this matter Solution System Business Headquarters